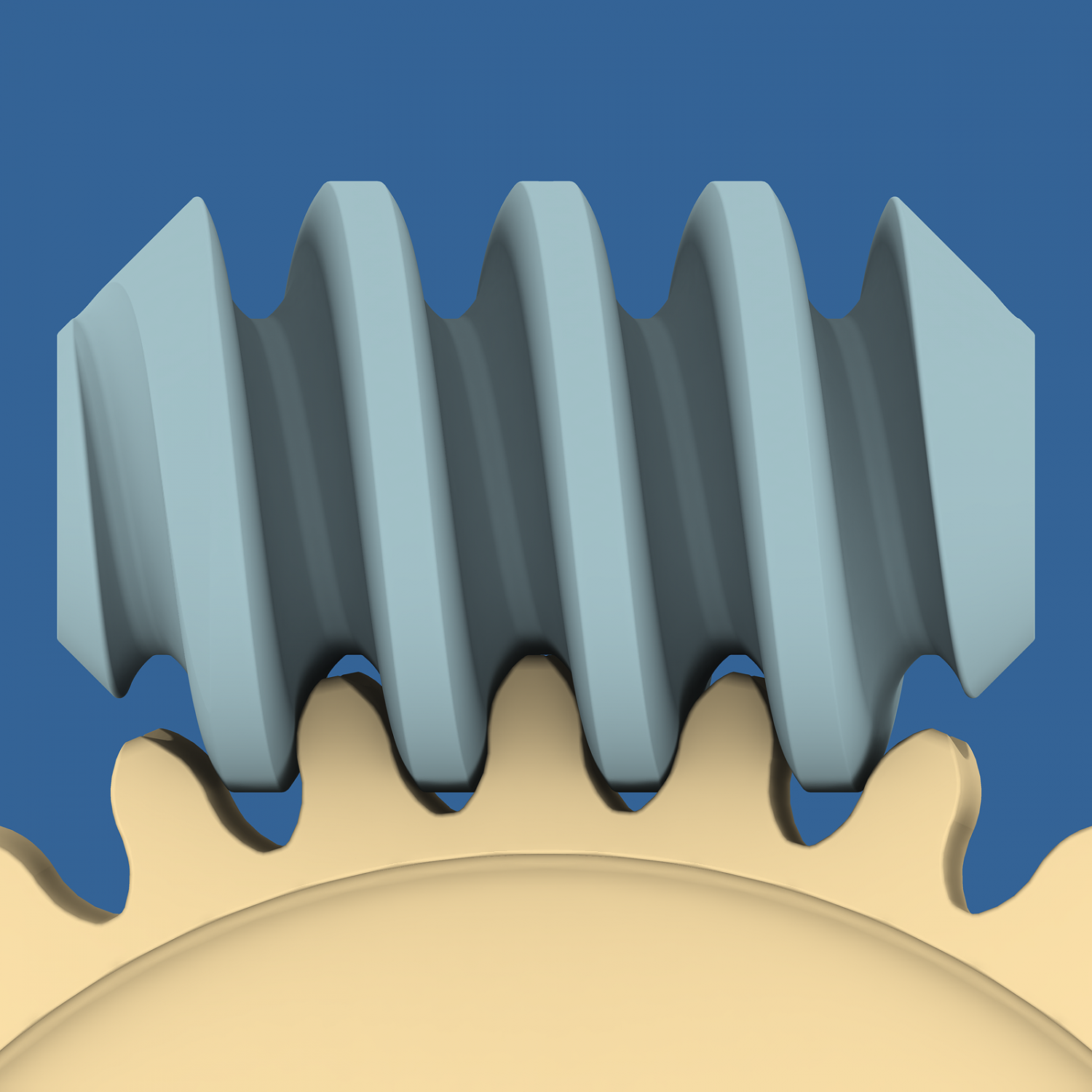

Arm gear and driving pinion life must be checked for wear and fatigue, as a function of your material selection and width of parts.

#Lego worm gear 3d model step manual

Fail-Safe operation – If the machine fails, a clinician must be able to immediately shut down, open the device manually, remove the bag and convert to manual bagging.

The bag must be supported with flexibility to allow motion during operation. The grippers must be smooth and shaped to maximise air expelled without damaging the bag. Any design must secure the bag and gently grasp and squeeze it from both sides to reduce the risk of material fatigue. Be nice to your bag and its hoses – Up to 7 day ✕ 24 hour ✕ 60 minute ✕ 30 bpm ✕ 2 stroke = 604,800 cycles will be needed for 7 day usage.Major mechanical design requirements include: This must be coupled with a closed loop control system. The basic concept consists of two arms that gently close in sync to compress the bag. We are in process of continually testing and refining our prototypes to increase robustness. Note: Any mechanical design must meet the specifications outlined in the Key Ventilation Specifications page. Finally mount the spare tracks and tools to each of their own respective locations on the rear of the vehicle.This section documents the mechanical design of the MIT Emergency Ventilator. Next attach the upper glacis (front) armor plate to the hull, and attach the rear hull roof to the back of the model. The Then attach the side armor via the dark blueish gray liftarms and the respective 3 long pins with friction. The 1圆 technic link will need to be attached to the towball for the elevation mechanism as well.

#Lego worm gear 3d model step install

The IR Remotes aren't included in the piece count.Īssembly of the LXF file is as follows, Install the M motor that is seperate from the model by inserting the blue pin on the bottom of the linear actuator into the perpendicular axle/pin connector next to the worm gear, and attach the front of the linear actuator to the blue pin attached to the traverse bracket located below the trunnion for the gun. It uses 95 treads per side, and the power functions extension cord is used to connect the battery to the 2 IR receivers. Then cut out and apply with transparent tape, or use decal paper. It features working independent suspension on all road wheels, 2 L motors for drivetrain, and 2 m motors for a 2 axis trunnion that can elevate/depress and rotate the 75mm cannon left/right.ĭecals for it,download original image and print them on paper. A 1/16 replica of a WWII Hetzer tank destroyer.

0 kommentar(er)

0 kommentar(er)